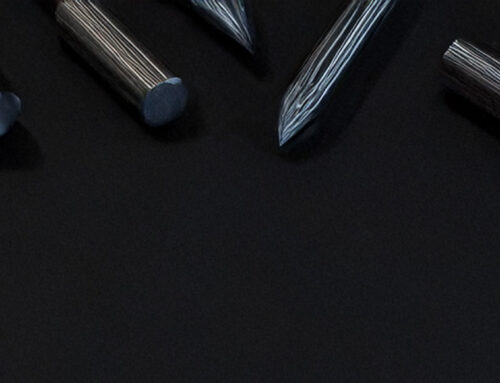

Sustainable Performance with Recycled Tungsten Carbide Industrial Razor Blades

At X-Keen Blades, we believe the future of industrial cutting lies in sustainability combined with high performance. That’s why we proudly introduce our latest innovation: industrial razor blades manufactured from recycled tungsten carbide. These blades represent the next generation of cutting technology—offering exceptional durability and precision while significantly lowering environmental impact.

Why Recycled Tungsten Carbide Is the Smarter Choice

Tungsten carbide is one of the hardest materials available, with hardness levels reaching up to HRC 92. This makes it invaluable for cutting tools that need to withstand heavy use without losing sharpness. Traditionally, producing tungsten carbide involves energy-intensive mining and refining processes.

By recycling tungsten carbide scrap, we bypass this environmentally costly step. The result? Blades that maintain the superior wear resistance and sharpness of newly mined tungsten carbide while contributing to a reduced carbon footprint.

For more background on how tungsten carbide scrap is collected, processed, and reused, you can explore resources such as Carbide Scrap Buyers. These insights underline why recycling is not only practical but also necessary in today’s industrial landscape.

Performance That Rivals Newly Mined Materials

Although the lifespan of recycled tungsten carbide blades can be slightly shorter than blades made from newly mined carbide, they still vastly outperform stainless steel and carbon steel alternatives. For many applications, this balance of performance, cost efficiency, and sustainability makes recycled tungsten carbide blades the obvious choice.

Industries no longer have to choose between precision and environmental responsibility. With X-Keen Blades, they get both.

Applications Across Industries for Recycled Blades

Our recycled tungsten carbide industrial razor blades are designed to deliver consistent performance across multiple demanding industries:

-

Packaging & Converting: Ensures clean and efficient cutting of films, foils, polyethylene (PE), and polypropylene (PP).

-

Textiles & Nonwovens: Handles woven fabrics, technical fibers, and delicate nonwoven materials with precision.

-

Paper & Printing: Offers smooth slitting of coated and laminated papers, reducing downtime and waste.

-

Plastics & Recycling: Designed for cutting recycled polymers, supporting circular economy initiatives without sacrificing quality.

Wherever precision and reliability are essential, X-Keen’s recycled tungsten carbide blades excel.

Recycled Tungsten Carbide: Benefits Beyond Cutting Performance

When you choose recycled tungsten carbide blades, you invest in more than cutting efficiency—you invest in responsible production and long-term value. The main advantages include:

-

Eco-Responsibility: Support sustainable industry practices by reusing valuable resources instead of mining new ones.

-

Operational Reliability: Achieve clean, sharp cuts that keep production lines efficient and downtime minimal.

-

Cost-Effectiveness: Experience high durability at a lower environmental and financial cost compared to traditional options.

By integrating sustainability directly into your cutting operations, you gain a competitive edge in a market increasingly shaped by environmental responsibility.

Available Sizes and Configurations in Recycled Blades

X-Keen’s recycled tungsten carbide blades are available in standard formats widely used across industries:

-

3-hole short blades: 43 x 22 mm

-

3-hole long slitter blades: 60 x 22 mm

These blades are ideal for converters and processors who require both precision and sustainability in their daily operations. With these configurations, we ensure compatibility with existing equipment while elevating cutting performance.

X-Keen Blades: Where Innovation Meets Sustainability

At X-Keen, we see sustainability not as an option, but as a responsibility. By pioneering recycled tungsten carbide technology, we empower businesses to optimize production processes while minimizing environmental impact. Our vision is to deliver cutting-edge tools that support both industrial efficiency and a greener future.

For manufacturers in packaging, textiles, paper, plastics, or recycling, our blades represent a forward-thinking choice that combines technical excellence with environmental awareness.

Conclusion

Recycled tungsten carbide industrial razor blades mark a new era in cutting technology. With their proven sharpness, reliability, and eco-friendly material base, they embody the perfect synergy of performance and sustainability.

By adopting X-Keen’s blades, you are not only improving your cutting operations—you are also contributing to a more sustainable industrial future. To understand more about the importance of tungsten carbide recycling and its role in the global supply chain, resources like Carbide Scrap Buyers provide further insights into this transformative process.

Choose X-Keen’s recycled tungsten carbide blades—the durable, sustainable, and future-ready solution for your cutting needs.